Contents

ESP32 THT PCB

We have transitioned from purely THT boards to combined SMD/THT boards.

Resistors and capacitors are now implemented as SMD components, enabling flexible partial assembly.

Here you can find information about the following revisions: 1.1

For each revision, the respective section contains information about known bugs, pin layout, features, and more.

Revision 1.1

KiCAD and Gerber files are available in our hardware repository: Minimal Rev 1.1

Bugs

Currently, there are no known bugs.

Connections on the ESP32 PCB Rev 1.6

| Header | Pin Software | Pin PCB | Connection |

|---|---|---|---|

| HT_RL | PIN 2 | OUT | SSR Heating |

| T_SENS | PIN 16 | SIG | Temperature sensor |

| I2C | PIN 21 | SDA | Display and pressure sensor - Pin SDA |

| I2C | PIN 22 | SCL | Display and pressure sensor - Pin SCL |

| V_IN | - | 5V | Switching power supply (5 Volt) |

| PV_RL | PIN 17 | Valve | Relay 3-way-valve |

| PV_RL | PIN 27 | Pump | Relay pump |

| BPSW_SW | PIN 34 | BREW | Brew switch or optocoupler |

| BPSW_SW | PIN 39 | PWR | Power switch |

| BPSW_SW | PIN 35 | STEAM | Steam switch |

| BPSW_SW | PIN 36 | WATER | Hot water switch (not yet implemented) |

| S_LED | PIN 26 | OUT | Status or Temp LED |

| W_SENS | PIN 23 | SIG | Water level sensor |

| SCALE | PIN 25 | DAT2 | Scale DAT2 |

| SCALE | PIN 32 | DAT | Scale DAT |

| SCALE | PIN 33 | CLK | Scale CLK |

| GPIO | PIN 1 | IO01 | Reserved for later use, e.g. Brew switch LED |

| GPIO | PIN 3 | IO03 | Reserved for later use, e.g. Rotary encoder CLK |

| GPIO | PIN 4 | IO04 | Reserved for later use, e.g. Rotary encoder DT |

| GPIO | PIN 5 | IO05 | Reserved for later use, e.g. Rotary encoder SW |

| GPIO | PIN 21 | SDA | Reserved for later use, e.g. IO Expander |

| GPIO | PIN 22 | SCL | Reserved for later use, e.g. IO Expander |

| GPIO | PIN 12 | IO12 | JTAG Debugger TDI |

| GPIO | PIN 13 | IO13 | JTAG Debugger TCK |

| GPIO | PIN 14 | IO14 | JTAG Debugger TMS |

| GPIO | PIN 15 | IO15 | JTAG Debugger TDO |

| GPIO | PIN 18 | IO18 | Reserved for later use, e.g. Dimmer ZC |

| GPIO | PIN 19 | IO19 | Reserved for later use, e.g. Steam switch LED |

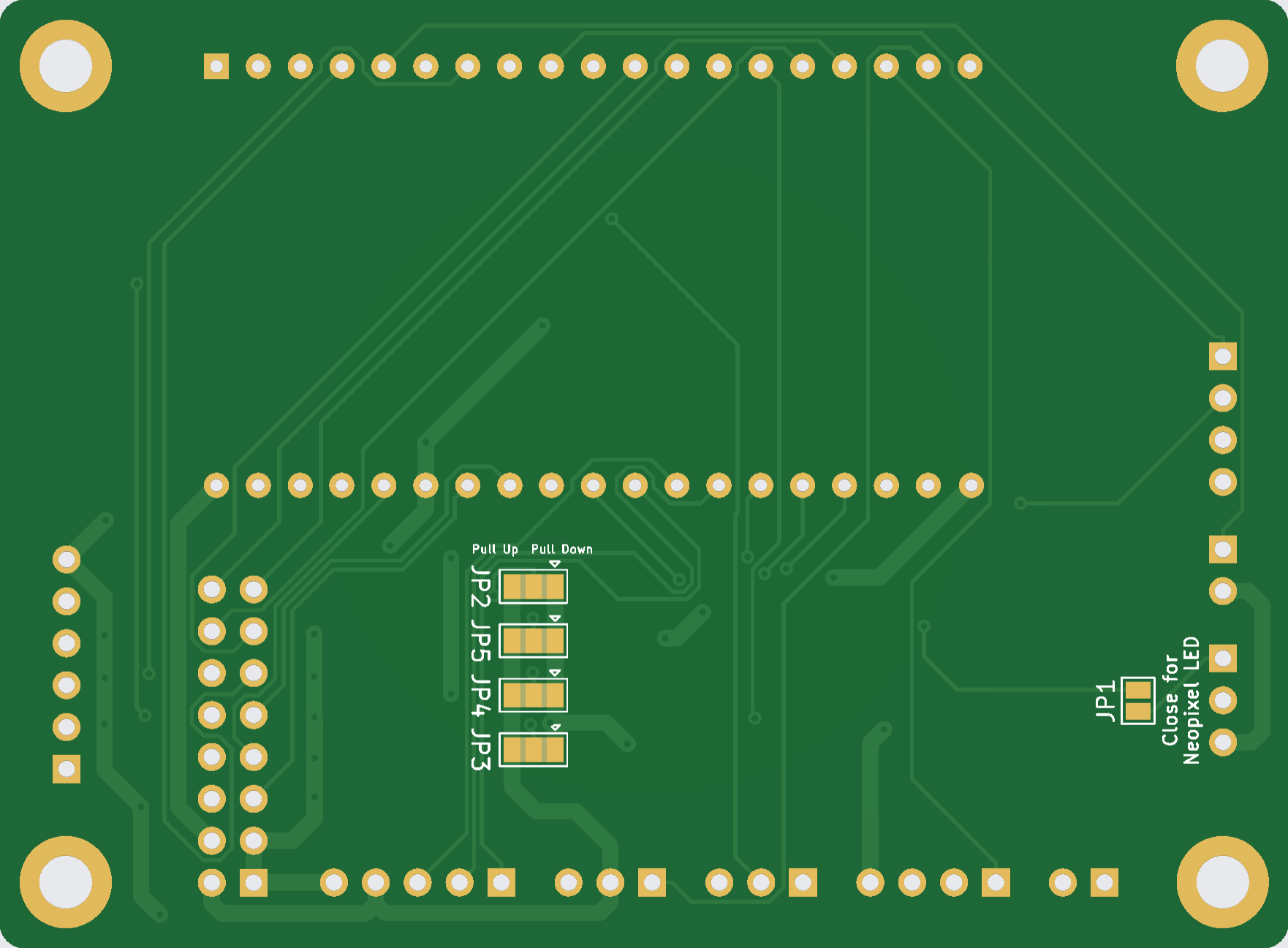

Placement and Function

All required parts and their function are listed here:

| Inscription PCB | Part | Function |

|---|---|---|

| C1 | Electrical capacitor 220 µF | Stabilization of power supply |

| C2 | Ceramic capacitor 100 nF | Stabilization of power supply |

| R1 | Resistor 220 Ω | Resistor Status LED |

| R2 | Resistor 47 kΩ | Pull down/up steam switch |

| R3 | Resistor 47 kΩ | Pull down/up power switch |

| R4 | Resistor 4,7 kΩ | Pull up i2C |

| R5 | Resistor 4,7 kΩ | Pull up i2C |

| R6 | Resistor 47 kΩ | Pull down/up brew switch or optocoupler |

| R7 | Resistor 47 kΩ | Pull down/up hot water switch |

| JP1 | Solder jumper | Resistor bypass for LED when using WS1812 LED |

| JP2 | Solder jumper | Pull down or Pull up for hot water switch |

| JP3 | Solder jumper | Pull down or Pull up for brew switch or optocoupler |

| JP4 | Solder jumper | Pull down or Pull up for power switch |

| JP5 | Solder jumper | Pull down or Pull up for steam switch |

Jumper Settings

The solder jumpers allow switching the resistors for the hot water, brew, power, and steam switches between pull-down and pull-up. The resistors define the state of the switch input when the switch is not actuated. The default configuration is that all jumpers are soldered to pull-down. When using an optocoupler for brew detection, in most cases solder jumper JP3 must be configured as pull-up.

Changes to THT Rev 1.6

- Resistors and capacitors implemented as SMD components

- Pull resistors for brew, hot water, steam, and power implemented via solder jumpers